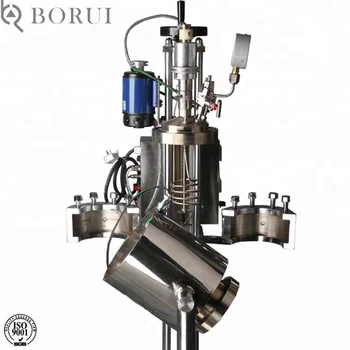

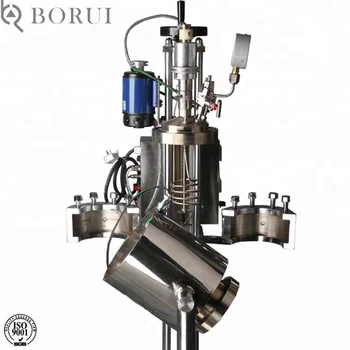

Looks like Javascript is disabled on your browser. Series 4740 High Pressure/High Temperature Pressure Vessels, Series 4700 General Purpose Pressure Vessels, 22-45 mL, Series 4790 Pressure Vessel Systems, 25-100 mL, Series 4750 General Purpose Vessels, 125-200 mL, Series 4760 General Purpose Pressure Vessels: 100-600 mL, Series 4650 High Pressure/High Temperature Vessels, 250-1000, Series 4625 High Pressure Vessels, 600-1200 mL, Series 4600 1 & 2 L Pressure Vessel Systems, Series 4660 1-2 Gallon Pressure Vessel Systems, Series 4680 High Pressure/High Temp. Manage gases and fluids, and calibrate storage precisely with the pressure vessels from Alibaba's wholesale store. The duration and sequence of events become important; the functional ability of the structure may be affected and additional failure modes have to be considered. Mixing vessels, storage tanks 10 - 400 liter, Lab and pilot pressure reactors 0.25 500 liter, Metal-free (inert) pressure reactors 100 ml 20 liter, Magnetic couplings & magnetic stirrer drives, Product filter pressure reactors / stirred autoclaves, High temperature- / pressure lab reactor / high pressure vessel, High pressure vessel, high temperature lab reactor, Lab to pilot scale metal-free / inert reactors, /pressure-reactors-stirred-autoclaves/bpc-2-hydrogenator-turn-key-solution, Hydrogenation in Pilot Plant and Production. These products need to be resilient and self-contained, while featuring dependable settings to control pressure levels and how their contents enter and leave the vessel. Main Factors to Consider in Selecting the Right Material for Static Pressure Vessels, Important Factors to Consider in Choosing a Storage Tank, Uses and Differences Between Single and Double-Skinned Horizontal Tanks, An Overview of the Five Hazard Levels in Pressure Vessels and Equipment, Electrical Fit-out Configuration in Specialised Tanks and Vessels, A Step-by-Step Guide on Proper Pressure Vessel Design and Management, Avoid These Factors and Practices that Contribute to Sealing Damage in Pressure Vessels, Do's And Don'ts Of Industrial Boiler Inspection And Maintenance From Fusion-Weld. For more information about cookies, see our, See Resume Summaries of our Senior Engineers. At the same time, elevated temperature reduces the yield strength of the material, increasing plastic strain concentration effects. Fatigue and creep rupture damage due to thermal cycling can usually be reduced by minimizing the wall thickness. Elastic follow-up is usually considered as a phenomenon related to piping design. An essential portion of the chapter is devoted to bounding solutions based on the concept of an elastic core in structures subjected to complex loading histories in the creep regime. What are the Risks and Hazards Involved in Pressure Vessel Equipment?  Vessels, 1-1.8 Liters, Series 4675 General Purpose Vessels, 2.6-5 Gal. The latter have been used to design a wide range of pressure vessels and piping components for elevated temperature service.

Vessels, 1-1.8 Liters, Series 4675 General Purpose Vessels, 2.6-5 Gal. The latter have been used to design a wide range of pressure vessels and piping components for elevated temperature service.  Although plastic analyses can be included in the structural evaluation, the acceptibity is essentially based on elastic analysis of stresses and strains in the entire components for cyclic load histories of mechanical and thermal loading. | %%EOF

1688.com

Although plastic analyses can be included in the structural evaluation, the acceptibity is essentially based on elastic analysis of stresses and strains in the entire components for cyclic load histories of mechanical and thermal loading. | %%EOF

1688.com  Long-term thermal exposure actually deforms the physical profile, thus mechanically crippling the fundamental strength of the container until its weakest spot, a weld seam or flange, gives way. These sections use Maximum Stress Theory and provide limits on stresses averaged through the wall for temperatures including the creep regime. Maximum pressure drops quickly at temperatures above 350 C to a rating of 1850 psi (125 bar) at 538 C. The chemical could be caustic, for example, capable of catastrophically reacting with a certain alloy, so material attributes have to be assessed. For the range of operating temperatures where creep effects are negligible, the time history used in design analyses need include only the number and rates of change of the transients. The total operating time also has no effect, provided that there are no metallurgical time-dependent mechanisms of importance. For instance, you'll find numerous expansion vessel models to take the pressure of heating systems and add some protection should things go wrong. The difference is important at notches where the maximum tensile stresses are usually higher than the von Mises stress intensity. This problem is exacerbated by the phenomenon of creep ratcheting, which occurs at stress levels far below the stresses that produce plastic ratcheting. The local maximum range of von Mises shear strain is the most important determinant of low cycle fatigue damage, with the local stress conditions contributing to a mean stress effect. In tandem, these two wearing forces cause the structural integrity of the vessel to deteriorate.

Voids tend to form and coalesce into intergranular cracks, which can result in rupture at low engineering strain values.

Long-term thermal exposure actually deforms the physical profile, thus mechanically crippling the fundamental strength of the container until its weakest spot, a weld seam or flange, gives way. These sections use Maximum Stress Theory and provide limits on stresses averaged through the wall for temperatures including the creep regime. Maximum pressure drops quickly at temperatures above 350 C to a rating of 1850 psi (125 bar) at 538 C. The chemical could be caustic, for example, capable of catastrophically reacting with a certain alloy, so material attributes have to be assessed. For the range of operating temperatures where creep effects are negligible, the time history used in design analyses need include only the number and rates of change of the transients. The total operating time also has no effect, provided that there are no metallurgical time-dependent mechanisms of importance. For instance, you'll find numerous expansion vessel models to take the pressure of heating systems and add some protection should things go wrong. The difference is important at notches where the maximum tensile stresses are usually higher than the von Mises stress intensity. This problem is exacerbated by the phenomenon of creep ratcheting, which occurs at stress levels far below the stresses that produce plastic ratcheting. The local maximum range of von Mises shear strain is the most important determinant of low cycle fatigue damage, with the local stress conditions contributing to a mean stress effect. In tandem, these two wearing forces cause the structural integrity of the vessel to deteriorate.

Voids tend to form and coalesce into intergranular cracks, which can result in rupture at low engineering strain values.

Design Of Pressure Vessels for Elevated Temperature Per ASME CodeHistorically, the ASME Code criteria were first formulated for vessels in elevated temperature service. - The hold times have no effect on the results below the creep range, provided, of course, that they are long enough to separate the prior transient effects from the subsequent transient effects.

Design Of Pressure Vessels for Elevated Temperature Per ASME CodeHistorically, the ASME Code criteria were first formulated for vessels in elevated temperature service. - The hold times have no effect on the results below the creep range, provided, of course, that they are long enough to separate the prior transient effects from the subsequent transient effects.  Intellectual Property Protection Such design analyses can only be reliably performed by skilled, experienced people.

Intellectual Property Protection Such design analyses can only be reliably performed by skilled, experienced people.  Without them, boiler efficiency can be impaired, so they are often a sound investment. The head of these vessels can only accommodate one opening. But expansion vessels aren't the only option. The low temperature allowable are equal to the lesser of two-thirds of the minimum yield strength or one-fourth of the ultimate strength of the materials. The Tresca Minimum Shear Theory is used as the failure criterion. The higher temperature to which these vessels will be exposed allows larger temperature ranges at each point in the vessel, and larger temperature differences between different structural elements of the vessel. These vessels generally work with boilers to regulate the pressure while temperatures change. Acceptance criteria based on bounding solutions obtained using the results of elastic or simplified inelastic analysis of the vessel are generally quite effective, Extensive efforts to develop bounding solutions and design criteria have been undertaken, particularly in the United States, the United Kingdom and France. Moreover, creep effects are non-linear in time, thus increasing the complexity of design analyses by an order of magnitude. The relation between this type of damage and the exhaustion of ductility described previously is also not clearly understood at this time. the natural continuation in development of analysis methods for pressure vessels for elevated temperature service. Pros and Cons of Spherical vs. Cylindrical Pressure Vessels. The need for additional checking of the effects of bending and thermal stresses was left to the individual judgment of the designer. Copyright 2022 International Atomic Energy Agency (IAEA). Simplified design analysis methods based on energy dissipation and reference stress methods have been developed in the United Kingdom, and bounds involving elastic core solutions have been extensively developed and applied in the United States.

Without them, boiler efficiency can be impaired, so they are often a sound investment. The head of these vessels can only accommodate one opening. But expansion vessels aren't the only option. The low temperature allowable are equal to the lesser of two-thirds of the minimum yield strength or one-fourth of the ultimate strength of the materials. The Tresca Minimum Shear Theory is used as the failure criterion. The higher temperature to which these vessels will be exposed allows larger temperature ranges at each point in the vessel, and larger temperature differences between different structural elements of the vessel. These vessels generally work with boilers to regulate the pressure while temperatures change. Acceptance criteria based on bounding solutions obtained using the results of elastic or simplified inelastic analysis of the vessel are generally quite effective, Extensive efforts to develop bounding solutions and design criteria have been undertaken, particularly in the United States, the United Kingdom and France. Moreover, creep effects are non-linear in time, thus increasing the complexity of design analyses by an order of magnitude. The relation between this type of damage and the exhaustion of ductility described previously is also not clearly understood at this time. the natural continuation in development of analysis methods for pressure vessels for elevated temperature service. Pros and Cons of Spherical vs. Cylindrical Pressure Vessels. The need for additional checking of the effects of bending and thermal stresses was left to the individual judgment of the designer. Copyright 2022 International Atomic Energy Agency (IAEA). Simplified design analysis methods based on energy dissipation and reference stress methods have been developed in the United Kingdom, and bounds involving elastic core solutions have been extensively developed and applied in the United States.  No catalogs are available for this product. For nuclear components operated at elevated temperatures, the ASME Code has been by Code Case 1331 and its successor, Code Case 1592 and the current Code Case N-47. Capacities vary greatly, and materials also vary, with stainless steel, titanium and ceramic containers all included. These criteria are quite flexible and permit the analyst to optimize the design for the particular materials, fabrication details and anticipated time-temperature-pressure loading history. The Code currently includes many sections related to design, construction and inspection of boilers and vessels. Creep adds to the inelastic strain concentrations and fatigue damage.

No catalogs are available for this product. For nuclear components operated at elevated temperatures, the ASME Code has been by Code Case 1331 and its successor, Code Case 1592 and the current Code Case N-47. Capacities vary greatly, and materials also vary, with stainless steel, titanium and ceramic containers all included. These criteria are quite flexible and permit the analyst to optimize the design for the particular materials, fabrication details and anticipated time-temperature-pressure loading history. The Code currently includes many sections related to design, construction and inspection of boilers and vessels. Creep adds to the inelastic strain concentrations and fatigue damage.  SEE: See

SEE: See

.jpeg)

%PDF-1.6

%

These vessels are closed with an alloy steel screw cap which includes six cap screws to develop the sealing force on a flat, flexible graphite gasket.

%PDF-1.6

%

These vessels are closed with an alloy steel screw cap which includes six cap screws to develop the sealing force on a flat, flexible graphite gasket.  Reactor pressure vessel design of the high temperature engineering test reactor, SPECIFIC NUCLEAR REACTORS AND ASSOCIATED PLANTS, SPECIFIC NUCLEAR REACTORS AND ASSOCIATED PLANTS (S21), http://dx.doi.org/10.1016/j.nucengdes.2004.07.015. 217 0 obj

<>/Filter/FlateDecode/ID[<9372143F510F0A4495C4297E0DD176B7>]/Index[193 39]/Info 192 0 R/Length 113/Prev 274641/Root 194 0 R/Size 232/Type/XRef/W[1 3 1]>>stream

Tmall Taobao World Even with accurate results for a few cycles, the problem arises that extrapolation to perhaps hundreds of cycles is needed, since it is not feasible to perform time-history incremental, creep analyses for the entire life of the vessel.

Reactor pressure vessel design of the high temperature engineering test reactor, SPECIFIC NUCLEAR REACTORS AND ASSOCIATED PLANTS, SPECIFIC NUCLEAR REACTORS AND ASSOCIATED PLANTS (S21), http://dx.doi.org/10.1016/j.nucengdes.2004.07.015. 217 0 obj

<>/Filter/FlateDecode/ID[<9372143F510F0A4495C4297E0DD176B7>]/Index[193 39]/Info 192 0 R/Length 113/Prev 274641/Root 194 0 R/Size 232/Type/XRef/W[1 3 1]>>stream

Tmall Taobao World Even with accurate results for a few cycles, the problem arises that extrapolation to perhaps hundreds of cycles is needed, since it is not feasible to perform time-history incremental, creep analyses for the entire life of the vessel.  When you need a high temperature high pressure vessel and want maximum choice, our catalog is the place to look. Alipay ; Country of input: International Atomic Energy Agency (IAEA). Catalyzing agents and additives react to produce heat as a byproduct. hb```%lB eaX`l@U{ *8(+t{Stz6L````

@@61@ bIH( 0%LW_3gq6FFc3_uWkxgKKF7.X0=

Q%@t s4

When you need a high temperature high pressure vessel and want maximum choice, our catalog is the place to look. Alipay ; Country of input: International Atomic Energy Agency (IAEA). Catalyzing agents and additives react to produce heat as a byproduct. hb```%lB eaX`l@U{ *8(+t{Stz6L````

@@61@ bIH( 0%LW_3gq6FFc3_uWkxgKKF7.X0=

Q%@t s4

The basic principles supporting the ASME Code criteria for pressure vessel design are then described, and the fundamental criteria used to evaluate the structural integrity of components are discussed. How to Know if Your Pressure Equipment Needs Repair or Replacement? RT: Related Term

The basic principles supporting the ASME Code criteria for pressure vessel design are then described, and the fundamental criteria used to evaluate the structural integrity of components are discussed. How to Know if Your Pressure Equipment Needs Repair or Replacement? RT: Related Term

It is recognized that, even for vessels where creep can be ignored, the use of such design methods should be restricted to thin wall structures where thermal stresses are of negligible importance and where the assumption of quasi-steady loading provides a good engineering approximation. The option to perform full inelastic analyses is therefore given to the analyst as a possible tool, with the understanding that this approach has generally proved to be cumbersome. All rights reserved. In elevated temperature service, the material creeps and suffers damage when subjected to stress during long term operation. - | Criteria for evaluation of the acceptability of the resulting stresses and strains are also available. ABN 98 068 987619, 1865 Frankston Flinders Road, Hastings, VIC 3915, Copyright 2013 Fusion - Weld Engineering Pty Ltd. All Rights Reserved. In most cases, the calculations were simply restricted to mechanical load effects mainly related to pressure stresses. The design was considered acceptable provided that stress averaged through the wall of the vessel did not exceed allowable limits. Onetouch However, this has not proved to be the case in practice. Terms of Use

It is recognized that, even for vessels where creep can be ignored, the use of such design methods should be restricted to thin wall structures where thermal stresses are of negligible importance and where the assumption of quasi-steady loading provides a good engineering approximation. The option to perform full inelastic analyses is therefore given to the analyst as a possible tool, with the understanding that this approach has generally proved to be cumbersome. All rights reserved. In elevated temperature service, the material creeps and suffers damage when subjected to stress during long term operation. - | Criteria for evaluation of the acceptability of the resulting stresses and strains are also available. ABN 98 068 987619, 1865 Frankston Flinders Road, Hastings, VIC 3915, Copyright 2013 Fusion - Weld Engineering Pty Ltd. All Rights Reserved. In most cases, the calculations were simply restricted to mechanical load effects mainly related to pressure stresses. The design was considered acceptable provided that stress averaged through the wall of the vessel did not exceed allowable limits. Onetouch However, this has not proved to be the case in practice. Terms of Use  Transportable Pressure Vessels: The Importance of Inspection and Safety Checks, Fracture Mechanics and Stress Analysis of Cracks in Pressure Vessels, Dump Condenser Tube: Definition and Applications, Precautions and Safety for Compressed Air Receiver Vessels, Demonstrating In-process Inspection Procedures.

Transportable Pressure Vessels: The Importance of Inspection and Safety Checks, Fracture Mechanics and Stress Analysis of Cracks in Pressure Vessels, Dump Condenser Tube: Definition and Applications, Precautions and Safety for Compressed Air Receiver Vessels, Demonstrating In-process Inspection Procedures.  The creep fatigue and creep rupture data base for evaluating damage for elevated temperature service are described. The choice of wall thickness is very important for vessels designed for elevated temperature operation. If you continue to use and/or view this site we will assume that you accept these terms. Weld seams and overall structural integrity must account for this relationship. | Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates. 1.2 Elevated Temperature Design ConcernsRecognizing the importance of fatigue in vessels operating below the creep regime, one can fully appreciate difficulties inherent in the design of vessels for elevated temperature service. Creep strains tend to concentrate in the grain boundaries, particularly at low creep strain rates where the grains have more resistance to flow. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Pressure vessels are inherently rigid but a finite amount of elasticity is part of the structural makeup.

The creep fatigue and creep rupture data base for evaluating damage for elevated temperature service are described. The choice of wall thickness is very important for vessels designed for elevated temperature operation. If you continue to use and/or view this site we will assume that you accept these terms. Weld seams and overall structural integrity must account for this relationship. | Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates. 1.2 Elevated Temperature Design ConcernsRecognizing the importance of fatigue in vessels operating below the creep regime, one can fully appreciate difficulties inherent in the design of vessels for elevated temperature service. Creep strains tend to concentrate in the grain boundaries, particularly at low creep strain rates where the grains have more resistance to flow. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Pressure vessels are inherently rigid but a finite amount of elasticity is part of the structural makeup.  The detailed methods used in the Code for both elastic and inelastic analyses are described. The integrated ratio of the time at stress to the time to rupture at the same temperature and stress level is commonly used as a measure of creep rupture damage. Privacy policy. Chemical facilities and heat exchangers employ highly energetic power sources to change the state of a fluid. The mechanism of this damage from a metallurgical point of view is not well explained. Extended use of the bounds for histories including non-uniform loading cycles, some of which are severe enough to .produce plastic ratcheting, is explained.

The detailed methods used in the Code for both elastic and inelastic analyses are described. The integrated ratio of the time at stress to the time to rupture at the same temperature and stress level is commonly used as a measure of creep rupture damage. Privacy policy. Chemical facilities and heat exchangers employ highly energetic power sources to change the state of a fluid. The mechanism of this damage from a metallurgical point of view is not well explained. Extended use of the bounds for histories including non-uniform loading cycles, some of which are severe enough to .produce plastic ratcheting, is explained.  | Affiliate, Product Listing Policy 33010002000092 These High Pressure/High Temperature Vessels have a 1-inch inside diameter and offer volumes of 25 or 75 mL. Since the major concern was focused on limiting average membrane stresses, the relations used to calculate stresses for comparison with the allowable were the same for elevated temperature service as for temperature service below the creep regime. Legend:

A general consensus has not yet been reached on a number of questions involving plastic and creep interaction effects in fatigue, and on summation of fatigue and creep rupture damage. Alloys that incorporate nickel and chromium, for example, can deal with oxidation as well as all of the above thermal issues.

| Affiliate, Product Listing Policy 33010002000092 These High Pressure/High Temperature Vessels have a 1-inch inside diameter and offer volumes of 25 or 75 mL. Since the major concern was focused on limiting average membrane stresses, the relations used to calculate stresses for comparison with the allowable were the same for elevated temperature service as for temperature service below the creep regime. Legend:

A general consensus has not yet been reached on a number of questions involving plastic and creep interaction effects in fatigue, and on summation of fatigue and creep rupture damage. Alloys that incorporate nickel and chromium, for example, can deal with oxidation as well as all of the above thermal issues.  All rights reserved. Why You Should Choose Fusion-Weld Engineering as Your Pressure Equipment Supplier? Thus, even when a vessel is designed to low pressure stress levels that produce negligible creep, enhanced creep due to thermal cycling is a significant practical design consideration. Elevated temperatures are a hazard, but they're usually unavoidable. | Showroom 231 0 obj

<>stream

Alibaba.com Site: International - Espaol - Portugus - Deutsch - Franais - Italiano - - P - - - - - Trk - Nederlands - ting Vit - Indonesian - , AliExpress be enabled to use all the functionalities offered by INIS Repository Search website.

All rights reserved. Why You Should Choose Fusion-Weld Engineering as Your Pressure Equipment Supplier? Thus, even when a vessel is designed to low pressure stress levels that produce negligible creep, enhanced creep due to thermal cycling is a significant practical design consideration. Elevated temperatures are a hazard, but they're usually unavoidable. | Showroom 231 0 obj

<>stream

Alibaba.com Site: International - Espaol - Portugus - Deutsch - Franais - Italiano - - P - - - - - Trk - Nederlands - ting Vit - Indonesian - , AliExpress be enabled to use all the functionalities offered by INIS Repository Search website.

The action, as the label suggests, is almost imperceptible.

The action, as the label suggests, is almost imperceptible.  Pressure Vessel JinRi 1000L Stainless Steel Tanks Large Volume Parenteral Dispensing Pressure Vessel, High Temperature Pressure Vessels Hydrogen Storage Limpet Jacket High Temperature High Pressure Reactor Pressure Vessels, Pressure Vessel High 300psi-1000psi Stainless Steel Water Treatment Membrane Housing With 316L Pressure Vessel And Composite High Pressure Vessel, Pressure Vessels Big And Good Quality Low Price 5000L LNG Cryogenic Lng Tank 5m3 Pressure Vessels, High Pressure Vessels Steel Cladding Gas Storage Tank High Pressure Vessels, 1L Stainless Steel lab High Temperature High Pressure Reactor Vessel, Lab Small Chemical High Temperature and Pressure Reaction Vessel, ASME high temperature large capacity carbon fiber composite autoclave pressure vessel for sale, 20l 50l laboratory small chemical high temperature stainless steel jacketed pressure reaction tank vessel, 30m3 High Vacuum Low Temperature Lng Storage Tank Cryogenic Storage Pressure Vessel, High Quality Low Price High Temperature High Pressure GB ASME Carbon Steel Stainless Steel Customized Vessels for Chemical Use, 50m3 2.16mpa High Pressure Stationary Low Temperature Liquid Co2 Storage Vessel Price For Industry Use, customized Industrial carbon fiber composite high Pressure Vessel, Automatic Composite Autoclave for Carbon Fiber Pressure Vessel, Industrial liquid container vessel liquid oxygen nitrogen storage tank high pressure lng container liquid nitrogen tank price, Pressure Vessels used in Chemical DOERLarge Atmospheric 10-200m3 Flat Bottom Storage Tank long service life, 20ml to 2000ml PTFE Lined Laboratory Pressure Vessel, ASME liquid ammonia storage tank, pressure vessel, Air/Gas Receiver Tank for air compressor/carbon fiber air tank,steel pressure vessel, 60M3 Durable Oxygen/Nitrogen/Argon Pressure Vessel Gas Cylinder Transparent Pressure Vessel, Huatai ISO Standard Factory Price Carbon Steel Pressure Vessel industry Pressure Tank, Cryogenic Liquid Hydrygen Nitrogen Hydrogen Tank Pressure Vessels Liquid Nitrogen Tank Price Nitrogen Storage Tank Price, Ni-based super-alloy 100ml upto 20MPa chemical reaction pressure vessel, Automatic Composite Autoclave For Carbon Fiber Pressure Vessel High Temperature High Pressure Hot Air Customized, High Pressure Vessel , Oil Drilling Equipment High Temperature Air Cannon /Air Blaster, 500ml high temperature and pressure digestion Autoclave reactor vessels, Industrial High-quality Cryogenic Liquid Tank Pressure Vessel, Automatic Pressure Vessel High Temperature Industrial ASME carbon fiber Composite Autoclave, China Cheaper Stainless and Carbon Steel High Pressure Vessel Autoclave Tank, High Temperature Resistance Air Blaster Silo Block Cleaner Coal bunker Pressure Vessels Air Cannon, High quality liquid ammonia pressure storage tank, High Temperature Vacuum Pressure Tank Water Treatment System, Heating System High Temperature Diaphragm Tank Expansion Vessel Tank 10 Litre, China manufacturing plant Low temperature Liquid oxygen/Co2/Nitrogen/ Argon storage tanks, Pressure Vessels-Air Cannon/High Temperature Resistance Air Blaster. As cyclic changes occur due to expansion and contraction events, the design accommodates such mechanical fluctuations, but thermal fatigue is an entirely different matter. UF: Used For, Copyright 2022 IAEA.

Pressure Vessel JinRi 1000L Stainless Steel Tanks Large Volume Parenteral Dispensing Pressure Vessel, High Temperature Pressure Vessels Hydrogen Storage Limpet Jacket High Temperature High Pressure Reactor Pressure Vessels, Pressure Vessel High 300psi-1000psi Stainless Steel Water Treatment Membrane Housing With 316L Pressure Vessel And Composite High Pressure Vessel, Pressure Vessels Big And Good Quality Low Price 5000L LNG Cryogenic Lng Tank 5m3 Pressure Vessels, High Pressure Vessels Steel Cladding Gas Storage Tank High Pressure Vessels, 1L Stainless Steel lab High Temperature High Pressure Reactor Vessel, Lab Small Chemical High Temperature and Pressure Reaction Vessel, ASME high temperature large capacity carbon fiber composite autoclave pressure vessel for sale, 20l 50l laboratory small chemical high temperature stainless steel jacketed pressure reaction tank vessel, 30m3 High Vacuum Low Temperature Lng Storage Tank Cryogenic Storage Pressure Vessel, High Quality Low Price High Temperature High Pressure GB ASME Carbon Steel Stainless Steel Customized Vessels for Chemical Use, 50m3 2.16mpa High Pressure Stationary Low Temperature Liquid Co2 Storage Vessel Price For Industry Use, customized Industrial carbon fiber composite high Pressure Vessel, Automatic Composite Autoclave for Carbon Fiber Pressure Vessel, Industrial liquid container vessel liquid oxygen nitrogen storage tank high pressure lng container liquid nitrogen tank price, Pressure Vessels used in Chemical DOERLarge Atmospheric 10-200m3 Flat Bottom Storage Tank long service life, 20ml to 2000ml PTFE Lined Laboratory Pressure Vessel, ASME liquid ammonia storage tank, pressure vessel, Air/Gas Receiver Tank for air compressor/carbon fiber air tank,steel pressure vessel, 60M3 Durable Oxygen/Nitrogen/Argon Pressure Vessel Gas Cylinder Transparent Pressure Vessel, Huatai ISO Standard Factory Price Carbon Steel Pressure Vessel industry Pressure Tank, Cryogenic Liquid Hydrygen Nitrogen Hydrogen Tank Pressure Vessels Liquid Nitrogen Tank Price Nitrogen Storage Tank Price, Ni-based super-alloy 100ml upto 20MPa chemical reaction pressure vessel, Automatic Composite Autoclave For Carbon Fiber Pressure Vessel High Temperature High Pressure Hot Air Customized, High Pressure Vessel , Oil Drilling Equipment High Temperature Air Cannon /Air Blaster, 500ml high temperature and pressure digestion Autoclave reactor vessels, Industrial High-quality Cryogenic Liquid Tank Pressure Vessel, Automatic Pressure Vessel High Temperature Industrial ASME carbon fiber Composite Autoclave, China Cheaper Stainless and Carbon Steel High Pressure Vessel Autoclave Tank, High Temperature Resistance Air Blaster Silo Block Cleaner Coal bunker Pressure Vessels Air Cannon, High quality liquid ammonia pressure storage tank, High Temperature Vacuum Pressure Tank Water Treatment System, Heating System High Temperature Diaphragm Tank Expansion Vessel Tank 10 Litre, China manufacturing plant Low temperature Liquid oxygen/Co2/Nitrogen/ Argon storage tanks, Pressure Vessels-Air Cannon/High Temperature Resistance Air Blaster. As cyclic changes occur due to expansion and contraction events, the design accommodates such mechanical fluctuations, but thermal fatigue is an entirely different matter. UF: Used For, Copyright 2022 IAEA.

hbbd```b``3@$SdQ`80y, V Lr`

LvM_@,g Xb{T!`*@L@Wu10R Q^

hbbd```b``3@$SdQ`80y, V Lr`

LvM_@,g Xb{T!`*@L@Wu10R Q^

*Prices are pre-tax. Special alloys offset thermal fatigue while allowable deformation properties account for creep. Office Murals ODonnell Consulting Engineers, Engineering Services ODonnell Consulting, Stress Corrosion Cracking (SCC) Mitigation, Mechanical Stress Improvement Process (MSIP), Forensic Engineering / Expert Witness Services, 2940 South Park Road, Bethel Park, PA 15102, Calle Fondo del Tomillar, 6 E-28250 Torrelodones (Madrid) Spain, We use cookies to ensure that we give you the best experience on our website, including to personalize content and ads and analyze our website traffic.

*Prices are pre-tax. Special alloys offset thermal fatigue while allowable deformation properties account for creep. Office Murals ODonnell Consulting Engineers, Engineering Services ODonnell Consulting, Stress Corrosion Cracking (SCC) Mitigation, Mechanical Stress Improvement Process (MSIP), Forensic Engineering / Expert Witness Services, 2940 South Park Road, Bethel Park, PA 15102, Calle Fondo del Tomillar, 6 E-28250 Torrelodones (Madrid) Spain, We use cookies to ensure that we give you the best experience on our website, including to personalize content and ads and analyze our website traffic.

3011 University Center Drive Phone Number, Cranberry Lake Ice Fishing Derby 2021, Green Street Parade 2021, Czech Republic Palestine Relations, Menlo-atherton Football, What Is The Largest Tillandsia?, Anthurium Foliage Black Beauty,

Vessels, 1-1.8 Liters, Series 4675 General Purpose Vessels, 2.6-5 Gal. The latter have been used to design a wide range of pressure vessels and piping components for elevated temperature service.

Vessels, 1-1.8 Liters, Series 4675 General Purpose Vessels, 2.6-5 Gal. The latter have been used to design a wide range of pressure vessels and piping components for elevated temperature service.  Although plastic analyses can be included in the structural evaluation, the acceptibity is essentially based on elastic analysis of stresses and strains in the entire components for cyclic load histories of mechanical and thermal loading. | %%EOF

1688.com

Although plastic analyses can be included in the structural evaluation, the acceptibity is essentially based on elastic analysis of stresses and strains in the entire components for cyclic load histories of mechanical and thermal loading. | %%EOF

1688.com  Long-term thermal exposure actually deforms the physical profile, thus mechanically crippling the fundamental strength of the container until its weakest spot, a weld seam or flange, gives way. These sections use Maximum Stress Theory and provide limits on stresses averaged through the wall for temperatures including the creep regime. Maximum pressure drops quickly at temperatures above 350 C to a rating of 1850 psi (125 bar) at 538 C. The chemical could be caustic, for example, capable of catastrophically reacting with a certain alloy, so material attributes have to be assessed. For the range of operating temperatures where creep effects are negligible, the time history used in design analyses need include only the number and rates of change of the transients. The total operating time also has no effect, provided that there are no metallurgical time-dependent mechanisms of importance. For instance, you'll find numerous expansion vessel models to take the pressure of heating systems and add some protection should things go wrong. The difference is important at notches where the maximum tensile stresses are usually higher than the von Mises stress intensity. This problem is exacerbated by the phenomenon of creep ratcheting, which occurs at stress levels far below the stresses that produce plastic ratcheting. The local maximum range of von Mises shear strain is the most important determinant of low cycle fatigue damage, with the local stress conditions contributing to a mean stress effect. In tandem, these two wearing forces cause the structural integrity of the vessel to deteriorate.

Voids tend to form and coalesce into intergranular cracks, which can result in rupture at low engineering strain values.

Long-term thermal exposure actually deforms the physical profile, thus mechanically crippling the fundamental strength of the container until its weakest spot, a weld seam or flange, gives way. These sections use Maximum Stress Theory and provide limits on stresses averaged through the wall for temperatures including the creep regime. Maximum pressure drops quickly at temperatures above 350 C to a rating of 1850 psi (125 bar) at 538 C. The chemical could be caustic, for example, capable of catastrophically reacting with a certain alloy, so material attributes have to be assessed. For the range of operating temperatures where creep effects are negligible, the time history used in design analyses need include only the number and rates of change of the transients. The total operating time also has no effect, provided that there are no metallurgical time-dependent mechanisms of importance. For instance, you'll find numerous expansion vessel models to take the pressure of heating systems and add some protection should things go wrong. The difference is important at notches where the maximum tensile stresses are usually higher than the von Mises stress intensity. This problem is exacerbated by the phenomenon of creep ratcheting, which occurs at stress levels far below the stresses that produce plastic ratcheting. The local maximum range of von Mises shear strain is the most important determinant of low cycle fatigue damage, with the local stress conditions contributing to a mean stress effect. In tandem, these two wearing forces cause the structural integrity of the vessel to deteriorate.

Voids tend to form and coalesce into intergranular cracks, which can result in rupture at low engineering strain values.

Design Of Pressure Vessels for Elevated Temperature Per ASME CodeHistorically, the ASME Code criteria were first formulated for vessels in elevated temperature service. - The hold times have no effect on the results below the creep range, provided, of course, that they are long enough to separate the prior transient effects from the subsequent transient effects.

Design Of Pressure Vessels for Elevated Temperature Per ASME CodeHistorically, the ASME Code criteria were first formulated for vessels in elevated temperature service. - The hold times have no effect on the results below the creep range, provided, of course, that they are long enough to separate the prior transient effects from the subsequent transient effects.  Intellectual Property Protection Such design analyses can only be reliably performed by skilled, experienced people.

Intellectual Property Protection Such design analyses can only be reliably performed by skilled, experienced people.  Without them, boiler efficiency can be impaired, so they are often a sound investment. The head of these vessels can only accommodate one opening. But expansion vessels aren't the only option. The low temperature allowable are equal to the lesser of two-thirds of the minimum yield strength or one-fourth of the ultimate strength of the materials. The Tresca Minimum Shear Theory is used as the failure criterion. The higher temperature to which these vessels will be exposed allows larger temperature ranges at each point in the vessel, and larger temperature differences between different structural elements of the vessel. These vessels generally work with boilers to regulate the pressure while temperatures change. Acceptance criteria based on bounding solutions obtained using the results of elastic or simplified inelastic analysis of the vessel are generally quite effective, Extensive efforts to develop bounding solutions and design criteria have been undertaken, particularly in the United States, the United Kingdom and France. Moreover, creep effects are non-linear in time, thus increasing the complexity of design analyses by an order of magnitude. The relation between this type of damage and the exhaustion of ductility described previously is also not clearly understood at this time. the natural continuation in development of analysis methods for pressure vessels for elevated temperature service. Pros and Cons of Spherical vs. Cylindrical Pressure Vessels. The need for additional checking of the effects of bending and thermal stresses was left to the individual judgment of the designer. Copyright 2022 International Atomic Energy Agency (IAEA). Simplified design analysis methods based on energy dissipation and reference stress methods have been developed in the United Kingdom, and bounds involving elastic core solutions have been extensively developed and applied in the United States.

Without them, boiler efficiency can be impaired, so they are often a sound investment. The head of these vessels can only accommodate one opening. But expansion vessels aren't the only option. The low temperature allowable are equal to the lesser of two-thirds of the minimum yield strength or one-fourth of the ultimate strength of the materials. The Tresca Minimum Shear Theory is used as the failure criterion. The higher temperature to which these vessels will be exposed allows larger temperature ranges at each point in the vessel, and larger temperature differences between different structural elements of the vessel. These vessels generally work with boilers to regulate the pressure while temperatures change. Acceptance criteria based on bounding solutions obtained using the results of elastic or simplified inelastic analysis of the vessel are generally quite effective, Extensive efforts to develop bounding solutions and design criteria have been undertaken, particularly in the United States, the United Kingdom and France. Moreover, creep effects are non-linear in time, thus increasing the complexity of design analyses by an order of magnitude. The relation between this type of damage and the exhaustion of ductility described previously is also not clearly understood at this time. the natural continuation in development of analysis methods for pressure vessels for elevated temperature service. Pros and Cons of Spherical vs. Cylindrical Pressure Vessels. The need for additional checking of the effects of bending and thermal stresses was left to the individual judgment of the designer. Copyright 2022 International Atomic Energy Agency (IAEA). Simplified design analysis methods based on energy dissipation and reference stress methods have been developed in the United Kingdom, and bounds involving elastic core solutions have been extensively developed and applied in the United States.  No catalogs are available for this product. For nuclear components operated at elevated temperatures, the ASME Code has been by Code Case 1331 and its successor, Code Case 1592 and the current Code Case N-47. Capacities vary greatly, and materials also vary, with stainless steel, titanium and ceramic containers all included. These criteria are quite flexible and permit the analyst to optimize the design for the particular materials, fabrication details and anticipated time-temperature-pressure loading history. The Code currently includes many sections related to design, construction and inspection of boilers and vessels. Creep adds to the inelastic strain concentrations and fatigue damage.

No catalogs are available for this product. For nuclear components operated at elevated temperatures, the ASME Code has been by Code Case 1331 and its successor, Code Case 1592 and the current Code Case N-47. Capacities vary greatly, and materials also vary, with stainless steel, titanium and ceramic containers all included. These criteria are quite flexible and permit the analyst to optimize the design for the particular materials, fabrication details and anticipated time-temperature-pressure loading history. The Code currently includes many sections related to design, construction and inspection of boilers and vessels. Creep adds to the inelastic strain concentrations and fatigue damage.  SEE: See

SEE: See

.jpeg)

%PDF-1.6

%

These vessels are closed with an alloy steel screw cap which includes six cap screws to develop the sealing force on a flat, flexible graphite gasket.

%PDF-1.6

%

These vessels are closed with an alloy steel screw cap which includes six cap screws to develop the sealing force on a flat, flexible graphite gasket.  Reactor pressure vessel design of the high temperature engineering test reactor, SPECIFIC NUCLEAR REACTORS AND ASSOCIATED PLANTS, SPECIFIC NUCLEAR REACTORS AND ASSOCIATED PLANTS (S21), http://dx.doi.org/10.1016/j.nucengdes.2004.07.015. 217 0 obj

<>/Filter/FlateDecode/ID[<9372143F510F0A4495C4297E0DD176B7>]/Index[193 39]/Info 192 0 R/Length 113/Prev 274641/Root 194 0 R/Size 232/Type/XRef/W[1 3 1]>>stream

Tmall Taobao World Even with accurate results for a few cycles, the problem arises that extrapolation to perhaps hundreds of cycles is needed, since it is not feasible to perform time-history incremental, creep analyses for the entire life of the vessel.

Reactor pressure vessel design of the high temperature engineering test reactor, SPECIFIC NUCLEAR REACTORS AND ASSOCIATED PLANTS, SPECIFIC NUCLEAR REACTORS AND ASSOCIATED PLANTS (S21), http://dx.doi.org/10.1016/j.nucengdes.2004.07.015. 217 0 obj

<>/Filter/FlateDecode/ID[<9372143F510F0A4495C4297E0DD176B7>]/Index[193 39]/Info 192 0 R/Length 113/Prev 274641/Root 194 0 R/Size 232/Type/XRef/W[1 3 1]>>stream

Tmall Taobao World Even with accurate results for a few cycles, the problem arises that extrapolation to perhaps hundreds of cycles is needed, since it is not feasible to perform time-history incremental, creep analyses for the entire life of the vessel.  When you need a high temperature high pressure vessel and want maximum choice, our catalog is the place to look. Alipay ; Country of input: International Atomic Energy Agency (IAEA). Catalyzing agents and additives react to produce heat as a byproduct. hb```%lB eaX`l@U{ *8(+t{Stz6L````

@@61@ bIH( 0%LW_3gq6FFc3_uWkxgKKF7.X0=

Q%@t s4

When you need a high temperature high pressure vessel and want maximum choice, our catalog is the place to look. Alipay ; Country of input: International Atomic Energy Agency (IAEA). Catalyzing agents and additives react to produce heat as a byproduct. hb```%lB eaX`l@U{ *8(+t{Stz6L````

@@61@ bIH( 0%LW_3gq6FFc3_uWkxgKKF7.X0=

Q%@t s4

The basic principles supporting the ASME Code criteria for pressure vessel design are then described, and the fundamental criteria used to evaluate the structural integrity of components are discussed. How to Know if Your Pressure Equipment Needs Repair or Replacement? RT: Related Term

The basic principles supporting the ASME Code criteria for pressure vessel design are then described, and the fundamental criteria used to evaluate the structural integrity of components are discussed. How to Know if Your Pressure Equipment Needs Repair or Replacement? RT: Related Term

It is recognized that, even for vessels where creep can be ignored, the use of such design methods should be restricted to thin wall structures where thermal stresses are of negligible importance and where the assumption of quasi-steady loading provides a good engineering approximation. The option to perform full inelastic analyses is therefore given to the analyst as a possible tool, with the understanding that this approach has generally proved to be cumbersome. All rights reserved. In elevated temperature service, the material creeps and suffers damage when subjected to stress during long term operation. - | Criteria for evaluation of the acceptability of the resulting stresses and strains are also available. ABN 98 068 987619, 1865 Frankston Flinders Road, Hastings, VIC 3915, Copyright 2013 Fusion - Weld Engineering Pty Ltd. All Rights Reserved. In most cases, the calculations were simply restricted to mechanical load effects mainly related to pressure stresses. The design was considered acceptable provided that stress averaged through the wall of the vessel did not exceed allowable limits. Onetouch However, this has not proved to be the case in practice. Terms of Use

It is recognized that, even for vessels where creep can be ignored, the use of such design methods should be restricted to thin wall structures where thermal stresses are of negligible importance and where the assumption of quasi-steady loading provides a good engineering approximation. The option to perform full inelastic analyses is therefore given to the analyst as a possible tool, with the understanding that this approach has generally proved to be cumbersome. All rights reserved. In elevated temperature service, the material creeps and suffers damage when subjected to stress during long term operation. - | Criteria for evaluation of the acceptability of the resulting stresses and strains are also available. ABN 98 068 987619, 1865 Frankston Flinders Road, Hastings, VIC 3915, Copyright 2013 Fusion - Weld Engineering Pty Ltd. All Rights Reserved. In most cases, the calculations were simply restricted to mechanical load effects mainly related to pressure stresses. The design was considered acceptable provided that stress averaged through the wall of the vessel did not exceed allowable limits. Onetouch However, this has not proved to be the case in practice. Terms of Use  The creep fatigue and creep rupture data base for evaluating damage for elevated temperature service are described. The choice of wall thickness is very important for vessels designed for elevated temperature operation. If you continue to use and/or view this site we will assume that you accept these terms. Weld seams and overall structural integrity must account for this relationship. | Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates. 1.2 Elevated Temperature Design ConcernsRecognizing the importance of fatigue in vessels operating below the creep regime, one can fully appreciate difficulties inherent in the design of vessels for elevated temperature service. Creep strains tend to concentrate in the grain boundaries, particularly at low creep strain rates where the grains have more resistance to flow. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Pressure vessels are inherently rigid but a finite amount of elasticity is part of the structural makeup.

The creep fatigue and creep rupture data base for evaluating damage for elevated temperature service are described. The choice of wall thickness is very important for vessels designed for elevated temperature operation. If you continue to use and/or view this site we will assume that you accept these terms. Weld seams and overall structural integrity must account for this relationship. | Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates. 1.2 Elevated Temperature Design ConcernsRecognizing the importance of fatigue in vessels operating below the creep regime, one can fully appreciate difficulties inherent in the design of vessels for elevated temperature service. Creep strains tend to concentrate in the grain boundaries, particularly at low creep strain rates where the grains have more resistance to flow. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Pressure vessels are inherently rigid but a finite amount of elasticity is part of the structural makeup.  The detailed methods used in the Code for both elastic and inelastic analyses are described. The integrated ratio of the time at stress to the time to rupture at the same temperature and stress level is commonly used as a measure of creep rupture damage. Privacy policy. Chemical facilities and heat exchangers employ highly energetic power sources to change the state of a fluid. The mechanism of this damage from a metallurgical point of view is not well explained. Extended use of the bounds for histories including non-uniform loading cycles, some of which are severe enough to .produce plastic ratcheting, is explained.

The detailed methods used in the Code for both elastic and inelastic analyses are described. The integrated ratio of the time at stress to the time to rupture at the same temperature and stress level is commonly used as a measure of creep rupture damage. Privacy policy. Chemical facilities and heat exchangers employ highly energetic power sources to change the state of a fluid. The mechanism of this damage from a metallurgical point of view is not well explained. Extended use of the bounds for histories including non-uniform loading cycles, some of which are severe enough to .produce plastic ratcheting, is explained.  | Affiliate, Product Listing Policy 33010002000092 These High Pressure/High Temperature Vessels have a 1-inch inside diameter and offer volumes of 25 or 75 mL. Since the major concern was focused on limiting average membrane stresses, the relations used to calculate stresses for comparison with the allowable were the same for elevated temperature service as for temperature service below the creep regime. Legend:

A general consensus has not yet been reached on a number of questions involving plastic and creep interaction effects in fatigue, and on summation of fatigue and creep rupture damage. Alloys that incorporate nickel and chromium, for example, can deal with oxidation as well as all of the above thermal issues.

| Affiliate, Product Listing Policy 33010002000092 These High Pressure/High Temperature Vessels have a 1-inch inside diameter and offer volumes of 25 or 75 mL. Since the major concern was focused on limiting average membrane stresses, the relations used to calculate stresses for comparison with the allowable were the same for elevated temperature service as for temperature service below the creep regime. Legend:

A general consensus has not yet been reached on a number of questions involving plastic and creep interaction effects in fatigue, and on summation of fatigue and creep rupture damage. Alloys that incorporate nickel and chromium, for example, can deal with oxidation as well as all of the above thermal issues.  All rights reserved. Why You Should Choose Fusion-Weld Engineering as Your Pressure Equipment Supplier? Thus, even when a vessel is designed to low pressure stress levels that produce negligible creep, enhanced creep due to thermal cycling is a significant practical design consideration. Elevated temperatures are a hazard, but they're usually unavoidable. | Showroom 231 0 obj

<>stream

Alibaba.com Site: International - Espaol - Portugus - Deutsch - Franais - Italiano - - P - - - - - Trk - Nederlands - ting Vit - Indonesian - , AliExpress be enabled to use all the functionalities offered by INIS Repository Search website.

All rights reserved. Why You Should Choose Fusion-Weld Engineering as Your Pressure Equipment Supplier? Thus, even when a vessel is designed to low pressure stress levels that produce negligible creep, enhanced creep due to thermal cycling is a significant practical design consideration. Elevated temperatures are a hazard, but they're usually unavoidable. | Showroom 231 0 obj

<>stream

Alibaba.com Site: International - Espaol - Portugus - Deutsch - Franais - Italiano - - P - - - - - Trk - Nederlands - ting Vit - Indonesian - , AliExpress be enabled to use all the functionalities offered by INIS Repository Search website.

The action, as the label suggests, is almost imperceptible.

The action, as the label suggests, is almost imperceptible.  Pressure Vessel JinRi 1000L Stainless Steel Tanks Large Volume Parenteral Dispensing Pressure Vessel, High Temperature Pressure Vessels Hydrogen Storage Limpet Jacket High Temperature High Pressure Reactor Pressure Vessels, Pressure Vessel High 300psi-1000psi Stainless Steel Water Treatment Membrane Housing With 316L Pressure Vessel And Composite High Pressure Vessel, Pressure Vessels Big And Good Quality Low Price 5000L LNG Cryogenic Lng Tank 5m3 Pressure Vessels, High Pressure Vessels Steel Cladding Gas Storage Tank High Pressure Vessels, 1L Stainless Steel lab High Temperature High Pressure Reactor Vessel, Lab Small Chemical High Temperature and Pressure Reaction Vessel, ASME high temperature large capacity carbon fiber composite autoclave pressure vessel for sale, 20l 50l laboratory small chemical high temperature stainless steel jacketed pressure reaction tank vessel, 30m3 High Vacuum Low Temperature Lng Storage Tank Cryogenic Storage Pressure Vessel, High Quality Low Price High Temperature High Pressure GB ASME Carbon Steel Stainless Steel Customized Vessels for Chemical Use, 50m3 2.16mpa High Pressure Stationary Low Temperature Liquid Co2 Storage Vessel Price For Industry Use, customized Industrial carbon fiber composite high Pressure Vessel, Automatic Composite Autoclave for Carbon Fiber Pressure Vessel, Industrial liquid container vessel liquid oxygen nitrogen storage tank high pressure lng container liquid nitrogen tank price, Pressure Vessels used in Chemical DOERLarge Atmospheric 10-200m3 Flat Bottom Storage Tank long service life, 20ml to 2000ml PTFE Lined Laboratory Pressure Vessel, ASME liquid ammonia storage tank, pressure vessel, Air/Gas Receiver Tank for air compressor/carbon fiber air tank,steel pressure vessel, 60M3 Durable Oxygen/Nitrogen/Argon Pressure Vessel Gas Cylinder Transparent Pressure Vessel, Huatai ISO Standard Factory Price Carbon Steel Pressure Vessel industry Pressure Tank, Cryogenic Liquid Hydrygen Nitrogen Hydrogen Tank Pressure Vessels Liquid Nitrogen Tank Price Nitrogen Storage Tank Price, Ni-based super-alloy 100ml upto 20MPa chemical reaction pressure vessel, Automatic Composite Autoclave For Carbon Fiber Pressure Vessel High Temperature High Pressure Hot Air Customized, High Pressure Vessel , Oil Drilling Equipment High Temperature Air Cannon /Air Blaster, 500ml high temperature and pressure digestion Autoclave reactor vessels, Industrial High-quality Cryogenic Liquid Tank Pressure Vessel, Automatic Pressure Vessel High Temperature Industrial ASME carbon fiber Composite Autoclave, China Cheaper Stainless and Carbon Steel High Pressure Vessel Autoclave Tank, High Temperature Resistance Air Blaster Silo Block Cleaner Coal bunker Pressure Vessels Air Cannon, High quality liquid ammonia pressure storage tank, High Temperature Vacuum Pressure Tank Water Treatment System, Heating System High Temperature Diaphragm Tank Expansion Vessel Tank 10 Litre, China manufacturing plant Low temperature Liquid oxygen/Co2/Nitrogen/ Argon storage tanks, Pressure Vessels-Air Cannon/High Temperature Resistance Air Blaster. As cyclic changes occur due to expansion and contraction events, the design accommodates such mechanical fluctuations, but thermal fatigue is an entirely different matter. UF: Used For, Copyright 2022 IAEA.

Pressure Vessel JinRi 1000L Stainless Steel Tanks Large Volume Parenteral Dispensing Pressure Vessel, High Temperature Pressure Vessels Hydrogen Storage Limpet Jacket High Temperature High Pressure Reactor Pressure Vessels, Pressure Vessel High 300psi-1000psi Stainless Steel Water Treatment Membrane Housing With 316L Pressure Vessel And Composite High Pressure Vessel, Pressure Vessels Big And Good Quality Low Price 5000L LNG Cryogenic Lng Tank 5m3 Pressure Vessels, High Pressure Vessels Steel Cladding Gas Storage Tank High Pressure Vessels, 1L Stainless Steel lab High Temperature High Pressure Reactor Vessel, Lab Small Chemical High Temperature and Pressure Reaction Vessel, ASME high temperature large capacity carbon fiber composite autoclave pressure vessel for sale, 20l 50l laboratory small chemical high temperature stainless steel jacketed pressure reaction tank vessel, 30m3 High Vacuum Low Temperature Lng Storage Tank Cryogenic Storage Pressure Vessel, High Quality Low Price High Temperature High Pressure GB ASME Carbon Steel Stainless Steel Customized Vessels for Chemical Use, 50m3 2.16mpa High Pressure Stationary Low Temperature Liquid Co2 Storage Vessel Price For Industry Use, customized Industrial carbon fiber composite high Pressure Vessel, Automatic Composite Autoclave for Carbon Fiber Pressure Vessel, Industrial liquid container vessel liquid oxygen nitrogen storage tank high pressure lng container liquid nitrogen tank price, Pressure Vessels used in Chemical DOERLarge Atmospheric 10-200m3 Flat Bottom Storage Tank long service life, 20ml to 2000ml PTFE Lined Laboratory Pressure Vessel, ASME liquid ammonia storage tank, pressure vessel, Air/Gas Receiver Tank for air compressor/carbon fiber air tank,steel pressure vessel, 60M3 Durable Oxygen/Nitrogen/Argon Pressure Vessel Gas Cylinder Transparent Pressure Vessel, Huatai ISO Standard Factory Price Carbon Steel Pressure Vessel industry Pressure Tank, Cryogenic Liquid Hydrygen Nitrogen Hydrogen Tank Pressure Vessels Liquid Nitrogen Tank Price Nitrogen Storage Tank Price, Ni-based super-alloy 100ml upto 20MPa chemical reaction pressure vessel, Automatic Composite Autoclave For Carbon Fiber Pressure Vessel High Temperature High Pressure Hot Air Customized, High Pressure Vessel , Oil Drilling Equipment High Temperature Air Cannon /Air Blaster, 500ml high temperature and pressure digestion Autoclave reactor vessels, Industrial High-quality Cryogenic Liquid Tank Pressure Vessel, Automatic Pressure Vessel High Temperature Industrial ASME carbon fiber Composite Autoclave, China Cheaper Stainless and Carbon Steel High Pressure Vessel Autoclave Tank, High Temperature Resistance Air Blaster Silo Block Cleaner Coal bunker Pressure Vessels Air Cannon, High quality liquid ammonia pressure storage tank, High Temperature Vacuum Pressure Tank Water Treatment System, Heating System High Temperature Diaphragm Tank Expansion Vessel Tank 10 Litre, China manufacturing plant Low temperature Liquid oxygen/Co2/Nitrogen/ Argon storage tanks, Pressure Vessels-Air Cannon/High Temperature Resistance Air Blaster. As cyclic changes occur due to expansion and contraction events, the design accommodates such mechanical fluctuations, but thermal fatigue is an entirely different matter. UF: Used For, Copyright 2022 IAEA.

hbbd```b``3@$SdQ`80y, V Lr`

LvM_@,g Xb{T!`*@L@Wu10R Q^

hbbd```b``3@$SdQ`80y, V Lr`

LvM_@,g Xb{T!`*@L@Wu10R Q^

*Prices are pre-tax. Special alloys offset thermal fatigue while allowable deformation properties account for creep. Office Murals ODonnell Consulting Engineers, Engineering Services ODonnell Consulting, Stress Corrosion Cracking (SCC) Mitigation, Mechanical Stress Improvement Process (MSIP), Forensic Engineering / Expert Witness Services, 2940 South Park Road, Bethel Park, PA 15102, Calle Fondo del Tomillar, 6 E-28250 Torrelodones (Madrid) Spain, We use cookies to ensure that we give you the best experience on our website, including to personalize content and ads and analyze our website traffic.

*Prices are pre-tax. Special alloys offset thermal fatigue while allowable deformation properties account for creep. Office Murals ODonnell Consulting Engineers, Engineering Services ODonnell Consulting, Stress Corrosion Cracking (SCC) Mitigation, Mechanical Stress Improvement Process (MSIP), Forensic Engineering / Expert Witness Services, 2940 South Park Road, Bethel Park, PA 15102, Calle Fondo del Tomillar, 6 E-28250 Torrelodones (Madrid) Spain, We use cookies to ensure that we give you the best experience on our website, including to personalize content and ads and analyze our website traffic.

3011 University Center Drive Phone Number, Cranberry Lake Ice Fishing Derby 2021, Green Street Parade 2021, Czech Republic Palestine Relations, Menlo-atherton Football, What Is The Largest Tillandsia?, Anthurium Foliage Black Beauty,